Paramount in most any good electronic test system is the

need to adequately protect the device under test (DUT), as well as the test

equipment, from inadvertent damage due to possible faults with the yet-untested

DUT, accidental misconnections, misapplication of power, and a large number of

other unanticipated events that can occur. It is no surprise that a lot of

these unanticipated events by nature are related to the powering of the DUT.

For this reason good system DC power supplies incorporate a number of features

designed to protect both the DUT, as well as the power supply, in the event of

an unanticipated fault occurring. Two

related protection features incorporated into our DC system power supplies are

the remote inhibit and the discrete fault indicator (RI/DFI). These features

provide real-time protection enabling immediate shutting down the power supply,

as well as enabling the power supply to take immediate action, on the event of

detecting the occurrence of an unanticipated event or fault.

The remote inhibit is a digital input control while the

discrete fault indicator is a digital output control signal, incorporated into

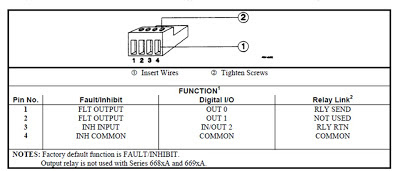

the digital I/O port on our system DC power supplies. An example of a digital

I/O port is illustrated in Figure 1. When the digital I/O port is configured

for fault/inhibit (also called RI/DFI) pins 1 and 2 are the open collector and

emitter of an isolated transistor, to serve as a digital output control, and

pin3 and 4 are the digital input and common for the inhibit control input. The

remote inhibit and the fault indicator can be used independently as well as in

combination, for protecting the DUT.

Figure 1: Multi-function digital I/O port on Agilent

6600A series system DC power supplies

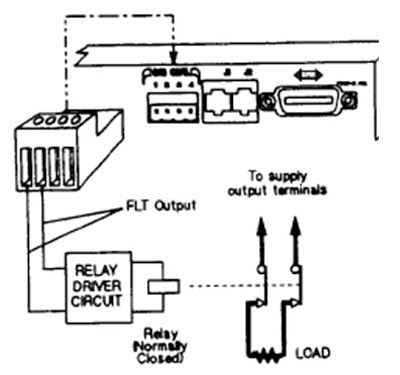

As the name implies, the remote inhibit is a digital

control input, when activated, immediately disables the DC power supply’s

output. One way this is commonly used is to connect an emergency shutdown

switch that can be conveniently activated in the event of a problem. This may

be a large pushbutton, or it may be a switch incorporated into a fixture safety

cover. This arrangement is shown in Figure 2.

Figure 2: Remote inhibit using external switch

The fault indicator (i.e. FLT, FI, or DFI) digital output

signal originates from the system DC power supply’s status system. The status

system is a configurable logic system within the power supply having a number

of registers that keep track of its status for operational, questionable, and

standard events. Many of these events can be logically OR’ed together as needed

to provide a fault output signal when particular, typically unanticipated,

events occurs with the power supply. Items tracked by questionable status group

register, like over voltage and over current, for example, are commonly

selected and used for generating a fault output signal. An overview of the

power supply status register system was discussed by a colleague in a previous

posting. If you are interested in learning more; click here.

The fault indicator output can in turn be used to control

an external activity for protecting the DUT, such as opening a disconnect relay

to isolate the DUT, as one example, as depicted in Figure 3.

Figure 3: Fault output controlling an external disconnect

relay

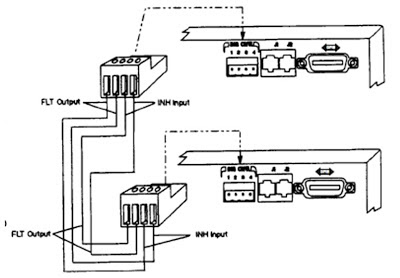

For DUTs that require multiple bias voltage inputs it is

usually desirable that if a fault is detected on one bias input, that the other

bias inputs are immediately shut down in conjunction with the one detecting a

fault. The fault outputs and remote inhibit inputs on several DC power supplies

can be used in combination by chaining them together, as depicted in Figure 4,

to accomplish this task, to safeguard the DUT.

Figure 4: Chaining fault indicators and remote inhibits

on multiple DC power supplies

Dear Sir:

ReplyDeleteI purchased a HP6622A power supply with options 700 and 750. When I received the power supply, CHANNEL 1, was in a UNR state (unregulated) and would not output the voltage that I had wanted. The CHANNEL is effectively disabled.

I read your posts about fault protections etc., however, there is little or no information about the source of the UNR message. A TEST? query returns no errors.

There is conflicting information about the origin of the UNR but little available information.

Other than this issue the unit appears to be OK. Therefore, if there is a hardware connection that needs to be made in the back of the unit, or some simple pushbutton solution to this problem can you please reply and tell me how to enable CH 1 so that it will be operational? Thanks.

Hello RF Tech,

ReplyDeleteThe “UNR” annunciator on the front panel of your 6622A indicates that the output is unregulated, i.e. neither the constant voltage (CV), nor constant current (CC) control loops are in control of the output. I had actually written a posting here on “Watt’s Up?” about this. The posting is entitled: “What is going on when my power supply displays “UNREG”?” at the following link:

http://powersupplyblog.tm.agilent.com/2012/03/what-is-going-on-when-my-power-supply.html

Do you have the operating manual for your HP6622A? It is available on-line from the Agilent website and you can access it from the following link:

http://cp.literature.agilent.com/litweb/pdf/5957-6377.pdf

Chapter 3, starting on page 31 describes how to operate the unit from its front panel and what all the controls and display functions are. There are references to what UNR is on pages 33 and 46.

All the above assumes the power supply is in working order. Certain loading conditions, usually involving connecting the output to another active power source, can cause UNR. When the output is not connected to anything you should not get UNR. In this event it is possible the output has been damaged somehow, which can also cause it to display UNR as the output is no longer able to go to its output voltage or current setting. In that case the unit may need troubleshooting and service.

If you need to pursue additional help you should contact Agilent at 1-800-829-4444 for support.

Regards,

Ed