The Advanced Power Supply family has a very slick way to parallel units for higher current called current sharing. This enables all of the paralleled units to be in Constant Voltage (CV) mode which is a change from most of our other power supplies that have one unit in CV mode and the rest of the units in Constant Current (CC) mode. My colleague Ed did a very informative blog post about the different paralleling options that explains a bit more about paralleling units so I will not rehash any of that here. Here is a link to that post: Paralleling Power Supplies.

The main drawback of the paralleling on the APS is that it can be a little difficult to get everything properly set to get the best performance. You need to synchronize your current measurements and your voltage transients. If you look in the manual, there are quite a few pages explaining how to set this all up. I am happy to say that we have made this a little easier. Our summer intern spent some time writing a VBA program in Excel that automatically does much of this. The program uses Keysight VISA-COM so you need to have the Keysight IO Libraries installed to use it. It will work with LAN, GPIB, and USB (all of which come standard on all APS units).

The first thing that we need to do is talk about the setup. There are quite a few wire connections that need to be made.

First you need to connect the current sharing ports, the sense connections, and the outputs to the load:

After that, you also need to make some connections on the 8 pin digital connector on the back of the APS units. You do not need to worry about setting up the pins if you plan on using the default pin assignments from the program. The default pin assignments are:

Pin 6 on all units - On Couple

Pin 7 on all units - Off Couple

Pin 1 on the master unit - Trigger Out

Pin 1 on all other units - Trigger In

Pin 8 on all units - common

Here is a wiring diagram of the default assignments (for 3 units):

The On/Off Couple Pins make it so that when you enable or disable the output on any unit, all of the units enable or disable. The trigger line enable us to synchronize measurements as well as voltage changes.

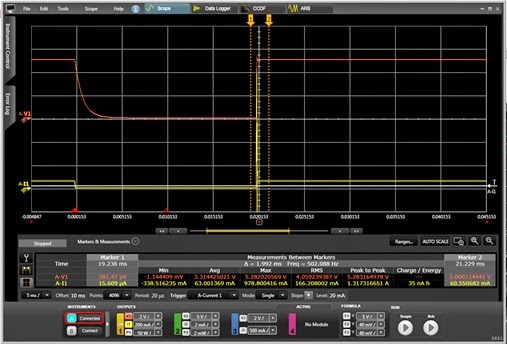

The Interface looks something like this:

It is divided into four boxes. I will refer to them as boxes 1 to 4 with 1 being the left most box. Box 1 is where you enter the VISA initialization string for each paralleled supply. You can get this from the Keysight IO Libraries. Box 2 is where you enter your settings You can set the voltage limit, positive and negative current limit, change the output state, and change the voltage. Most importantly, this is where you set the number of paralleled units. This needs to be done or else the program will not work correctly. You can parallel 1 kW and 2 kW units with each other, as long as they have the same maximum voltage so we also need to break out the number of 2 kW units in the scheme. The third box will do a scalar measurement of the voltage and current. This will report the total current of the paralleled units (it does a triggered measurement and adds all of the current measurements). The fourth box will measure arrays of current and voltage (this function will not work on the N6900 APS units).

I have posted this program on our Keysight Power Supply Forums at: Matt's Forum Post. I have also opened a thread there where we can discuss this program. It is still kind of preliminary so any feedback could possibly be incorporated into the program.

That is all I have for this month. Happy Halloween to all of our readers and please let me know any comments in the forum.