Occasionally when working with customers on power supply

applications that require sourcing and sinking current which can be addressed

with the proper choice of a two-quadrant power supply, I am told “we need a

four-quadrant power supply to do this!” I ask why and it is explained to me

that they want to sink current down near or at zero volts and it requires

4-quadrant operation to work. The reasoning why is the case is illustrated in

Figure 1.

As can be seen in the diagram, in practical applications

when regulating a voltage at the DUT when sinking current, the voltage at the

power supply’s output terminals will be lower than the voltage at the DUT, due

to voltage drops in the wiring and connections. Often this means the power

supply’s output voltage at its terminals will be negative in order to regulate

the voltage at the DUT near or at zero volts.

Hence a four-quadrant power supply is required, right? Well,

not necessarily. It all depends on the choice of the two-quadrant power supply

as they’re not all the same! Some two-quadrant power supplies will regulate

right down to zero volts even when sinking current, while others will not. This

can be ascertained from reviewing their output characteristics.

Our N6781A, N6782A, N6785A and N6786A are examples of

some of our two-quadrant power supplies that will regulate down to zero volts

even when sinking current. This is

reflected in the graph of their output characteristics, shown in Figure 2.

Figure 2: Keysight N6781A, N6782A, N6785A and N6786A

2-quadrant output characteristics

What can be seen in Figure 2 is that these two-quadrant

power supplies can source and sink their full output current

rating, even along the horizontal zero volt axis of their V-I output

characteristic plots. The reason why they are able to do this is because

internally they do incorporate a negative voltage power rail that allows them

to regulate at zero volts even when sinking current. While you cannot program a

negative output voltage on them, making them two-quadrants instead of four,

they are actually able to drive their output terminals negative by a small

amount, if necessary. This will allow them to compensate for remote sense

voltage drop in the wiring, in order to maintain zero volts at the DUT while

sinking current. This also makes for a more complicated and more expensive

design.

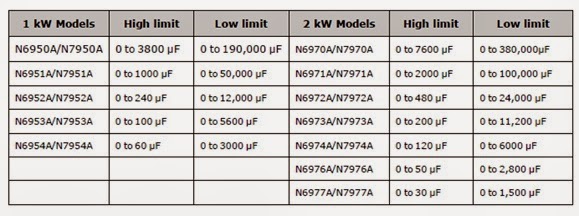

Our N6900A and N7900A series advanced power sources (APS)

also have two-quadrant outputs. Their output characteristic is shown in Figure

3.

Figure 3: Keysight N6900A and N7900A series 2-quadrant

output characteristics

Here, in comparison, a certain amount of minimum positive

voltage is required when sinking current. It can be seen this minimum positive

voltage is proportional to the amount of sink current as indicated by the sloping

line that starts a small maximum voltage when at maximum sink current and

tapers to zero volts at zero sink current. Basically these series of 2-quadrant power

supplies are not able to regulate down to zero volts when sinking current.

The reason why is because they do not have an internal negative power voltage

rail that is needed for regulating at zero volts when sinking current.

So when needing to source and sink current and power near

or at zero volts do not immediately assume a 4-quadrant power supply is

required. Depending on the design of a 2-quadrant power supply, it may meet the

requirements, as not all 2-quadrant power supplies are the same! One way to

tell is to look at its output characteristics.