A higher level of voltage accuracy is usually always needed

for powering electronic devices under test (DUTs). Many devices provide guaranteed

specifications for operating at minimum, nominal, and maximum voltages, so the

voltage needs to accurate as to not require unacceptable amounts of guard

banding of the voltage settings.

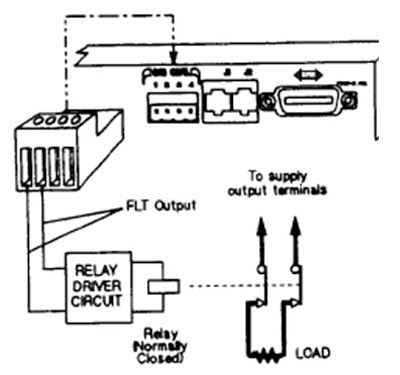

One very significant factor that affects the accuracy of

the voltage at the DUT is the voltage drop in the wiring between the output

terminals of the power supply and the actual DUT fixture, due to wiring’s

inherent resistance, as shown in Figure 1.

A standard feature

of most all system DC power supplies is remote voltage sensing. Instead of the

voltage being regulated at the output terminals of the DC power supply’s output

terminal, it is instead sensed and regulated at the DUT itself, compensating

for the voltage drop in the wiring. Additional details of this are documented

in an earlier posting: “Use remote sense to regulate voltage at your load”

While remote voltage sensing addresses the problem of

voltage drop in wiring affecting the voltage accuracy at the DUT, it then

raises the concern of what happens if one of the sense lines becomes disconnected.

Will the DC power supply voltage climb up to it maximum potential causing my

DUT to be damaged? Although this is a

very legitimate concern, often the voltage is usually kept within a reasonable

range of the setting by a feature referred to as “open sense lead protection”. A

deeper dive on the issue of open sense lines and open sense lead protection are

discussed at our posting: “What happens if remote sense leads open?”

Even with open sense lead protection and the voltage

being kept within a reasonable range of the setting, this can be a concern for

some customers who are relying on a high level of DC voltage accuracy at the

DUT for test and calibration purposes. One categorical example of this is

battery powered devices, where ADC circuits that need to precisely monitor the

battery input voltage have to be accurately calibrated. If the voltage from the

DC power supply has significant error, the DUT will be miss-calibrated.

One issue with open sense lead protection is it is a

passive protection mechanism. It is simply a back up that takes over when a

sense line is open. There is no way of knowing the sense lead is open. No error

flag is set or fault condition tripped. The voltage being read back is the same

as that is being regulated by the voltage sensing error amplifier, which is the

same as the set voltage, so all looks fine from a read-back perspective. This

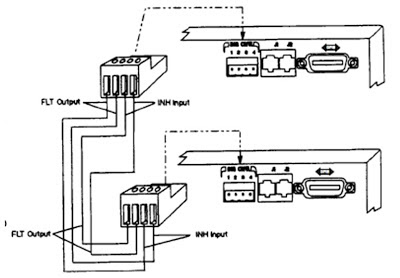

is where open sense lead detection takes over. Open sense lead detection is a

system that actively checks to see if the sense lines are doing their job. If

not it lets the test system know there is a fault.