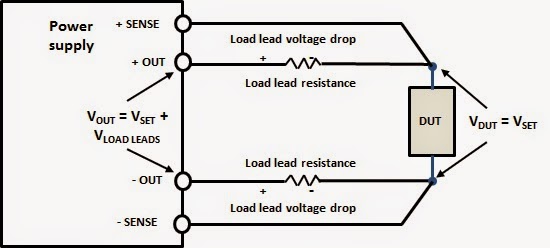

The remote sense lines are a vital part of any good

system power supply. As shown in Figure 1, by using a second, separate pair of leads

for sensing, the output voltage is now regulated right at the DUT rather than

at the output terminals on the power supply. Any voltage drops in the force

leads are compensated for; assuring the highest possible voltage accuracy is

achieved right at the DUT.

Figure 1: Remotely sensing and regulating output voltage

at the DUT

Of course for this to work correctly the sense leads need

to have a good connection at the DUT. However, what if the sense leads become

disconnected, misconnected, or shorted?

One might think if one or both of the sense leads became

disconnected, the sensed voltage would then become zero, causing the output

voltage on the force leads to climb up out of control until the over voltage

protect (OVP) trips. This turns out not to be the case, as a co-contributor

here, Gary had pointed out in a previous posting “What happens if remote sense

leads open?” (Click here to review). Basically a passive protection mechanism

called sense protect maintains a backup connection between the sense line and

corresponding output terminal inside the power supply in the event of a sense

line becoming disconnected.

While sense protect is an indispensable feature to help

protect your DUT by preventing runaway over-voltage, if a sense lead is open

the voltage at your DUT is still not as accurate as it should be due to

uncompensated voltage drops in the force leads. This can lead to miscalibrated

DUTs and you would not even know that it is happening. To address this some

system power supplies include an active open sense lead fault detection system.

As one example our 663xx Mobile Communications DC Sources check the sense lead

connections during each output enable and will issue a fault protect and shut

down the output if one or both sense leads become disconnected. It will also

let you know which of the sense leads are disconnected. It can be enabled and

disabled as needed. I had written about this in a previous posting “Open sense

lead detection, additional protection for remote voltage sensing” (Click here to review).

Taking sense protection further, we have incorporated a

system we refer to as sense fault detect (SFD) in our N6900A and N7900A

Advanced Power System (APS). It can be enabled or disabled. When enabled it

continually monitors the sense lead connections at all times. If it detects a

sense fault it sets a corresponding bit in the questionable status group

register as well as turn on status annunciator on the front panel to alert the

user, but does not disable the output. Through the expression signal routing

system a “smart trigger” can be configured as shown in Figure 2 to provide a

protect shutdown on the event of a sense fault detection. In all, sense fault detect on APS provides a

higher level of protection and flexibility.

Figure 2: Configuring a custom opens sense fault protect

on the N6900/N7900 APS

What happens if the sense leads become shorted? Unlike

open sense leads, in this case the output voltage can rise uncontrolled. The

safeguard for this relies on the over voltage protect system. The same thing

happens if the sense leads are reversed. The power supply will think the output

voltage is too low and keep increasing the output voltage in an attempt to

correct it. Again the safeguard for this relies on the over voltage protect

system. The N6900/N7900 APS does actually distinguish the difference when the

sense leads are reversed by generating a negative OVP (OV-) fault, giving the

user more insight on what the fault is to better help in rectifying the

problem.

Remote voltage sensing provides a great benefit by being

able to accurately control the voltage right at the DUT. Along with the

appropriate safeguards against sense lead misconnections you get all the

benefit without any of the corresponding risks!