Hi everybody!

My blog post this month is the result of a recent customer question. The question was: how do you synchronize measurements

with list transients? The short answer

is that you use the built in digitizer to generate enough points to sample the

measurements over the entire transient. The

rest of this blog will provide the long answer.

The program that I am using here was written for a N6762A DC Power

Module but the technique will work with any power supply that has a built in

digitizer such as the Advanced Power System or any N6700 module with option

054.

For simplicity’s sake, we are going to use a 5 point

list. The voltage steps are 1 V, 2 V, 3 V,

4 V, and 5 V and the dwell times are 0.1 s, 0.2 s, 0.3 s, 0.4 s, and 0.5 s. Let’s first set the list up (please note that

all programming is done in VB.net with VISA-COM):

The next thing to do is to set up the measurement

system. We need to figure out the total

number of points that we need measure so that we can cover the entire transient. The first thing that we need to do is to

calculate the total time of the list transient (you can even do this in your

program):

The total time of our transient is 1.5 s. Now we need to use this to figure out the

number of points. I am going to choose a measurement interval of 40.96 us. This means that we want to take a measurement

every 40.96 us for 15 s. To get the

total number of points, you need to divide the total transient time by the

measurement time interval:

I’m going to round down and use 36,621

points. I’m also going to tell the power

supply to use the binary data format because as we know from my previous blog

posts, this is the fastest way to read back data. Here

is the code to set up the digitizer:

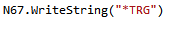

We will set our trigger source to bus for

both the transient system and the acquire system:

Next we initiate both systems:

Once the initiate is complete, we send a

trigger:

This will start both the list transient

and the digitizer. After everything is

completed, we can fetch our measured voltage array:

This array will have all of our

measurements.

I hope that this has been useful, have a

good month everyone.