1. How long does it take for a power supply output voltage to change from one value to another value?

2. How long does it take for a power supply output voltage to recover to its original value following a load current change?

This customer wanted to know the answer to question 1. Luckily, both of these answers can be found in our specifications and supplemental characteristic tables.

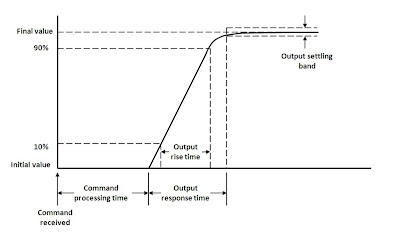

Question 1 is referring to a supplemental characteristic that has a variety of similar names: programming speed, settling time, output response time, output response characteristic, and programming response time. This is typically described with rise time and fall time values, or settling time values, or occasionally with a time constant. Rise (and fall) time values are what you would expect: the time it takes for the output voltage to go from 10% of its final value to 90% of its final value. Settling time (labeled “Output response time” in the graph below) is the time from when the output voltage begins to change until it settles within a specified settling band around the final value, such as 1% or even 0.1%, or sometimes within an LSB (least significant bit) of the final value. My fellow blogger, Ed, posted about how this affects throughput (click here) back in September of 2013.

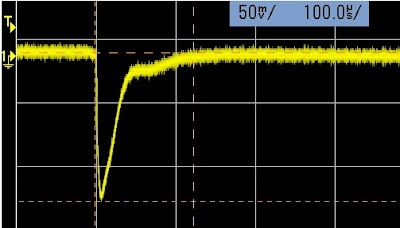

Question 2 is referring to a specification called transient response, or load transient recovery time. Whenever the load current changes from a low current to a higher current, the output voltage temporarily dips down slightly and then quickly recovers back to the original value (or close to it).

The feedback loop design inside the power supply determines how quickly the voltage recovers from this load current change. Higher bandwidth designs recover more quickly but are less stable. Likewise, lower bandwidth designs recover more slowly and are more stable. Ed posted about optimizing the output response back in April of this year (click here).

So the transient response recovery time is the time from when the load current begins to increase (coincident with the output voltage beginning to drop) to when the output voltage settles within a specified settling band around the final voltage value.

Our customer was interested in a “fast” power supply, meaning one with a settling time to meet his needs. Once we understood what he needed, we directed him to a power supply that could easily meet his requirements!

.jpg)

.jpg)