In part 1 of this posting on simulating battery contact

bounce (click here to review) I discussed what battery contact bounce is about and

why creating a voltage dropout may not be adequate for simulating battery

contact bounce. The first answer to addressing this was provided; use a

blocking diode and then a voltage dropout is certain to be suitable for

simulating battery contact bounce.

Another approach for simulating battery contact bounce is

to add a solid state switch between the DC source and the battery powered

device. While this is a good approach it is complex to implement. A suitable

solid state switch needs to be selected along with coming up with an

appropriate way to power and drive the input of the switch need to be

developed.

If for some reason using a blocking diode is not

suitable, there is yet another fairly simple approach that can be taken to

simulate high impedance battery contact bounce. Instead of programming a

voltage dropout on the DC source, program a current dropout. Where the voltage

going to zero during a voltage dropout is effectively a short circuit, as we saw

in part 1, the current going to zero during a current dropout is effectively an

open circuit. There are a couple of caveats for doing this. The main one is

battery powered devices are powered from a battery, which is a voltage source,

not a current source. In order for the DC source to act as a voltage source

when delivering power, we need to rely on the DC source voltage limit being set

to the level of the battery voltage. In order for this to happen we need to set

the non-dropout current level to be in excess of the maximum level demanded by

the device being powered and. Thus the DC source will normally be operating in

voltage limit. Then when the current dropout drives the output current to zero,

the DC source switches its operating mode from voltage limit to constant

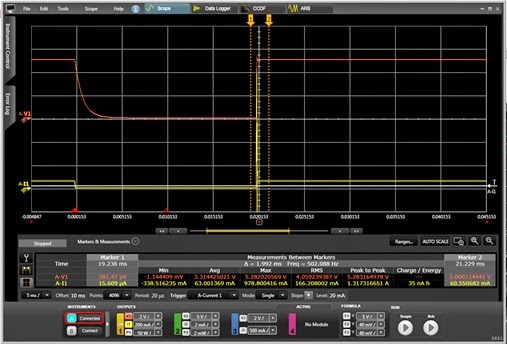

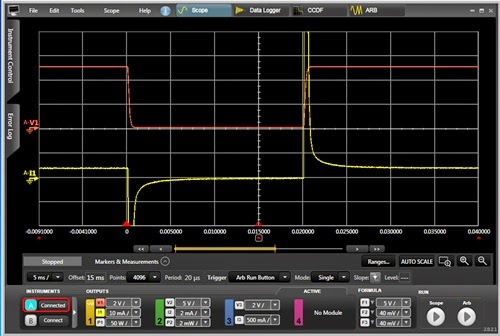

current, with a current value of zero. This operation is depicted in Figure 4,

using a Keysight N6781A 2-quadrant SMU module designed for testing battery

powered devices, operating within an N6705B DC Power Analyzer. In this example

the current ARB for the dropout was both programmed and the results shown in

Figure 1 captured using the companion 14585A software.

Figure 1: Current ARB creates a high impedance dropout to

simulate battery contact bounce

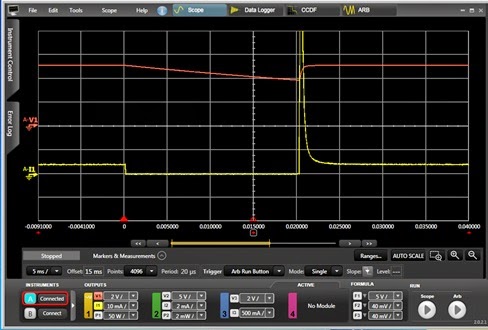

Another caveat with using this approach for simulating

battery contact bounce is paying careful attention to the behavior of the mode

crossovers. For the first crossover, from voltage limit to constant current

operation (at zero current) there is a small amount of lag time, typically just

a fraction of a millisecond, before the transition happens. This becomes more

significant only when trying to simulate extremely short contact bounce

periods. More important is when crossing back over from constant zero current

back to voltage limit operation. There is a short period when the current goes

up to its high level before the voltage limit gains control, holding the

voltage at the battery’s voltage level. Usually any capacitance at the input of

the DUT will normally absorb any short spike of current. If this crossover is

slow enough, and there is very little or no capacitance, the device could see a

voltage spike. The N6781A has very fast responding circuits however, minimizing

crossover time and inducing just 250 mV of overshoot, as is seen in Figure 1.

Hopefully, now armed with all of these details, you will

be able to select an approach that works best for you for simulating battery

contact bounce!