Hello everyone! Today

I am going to talk about how to use the Operation Status and Questionable

Status Registers on Agilent’s power supplies.

All of Agilent’s SCPI based power supplies use these registers. Figure 1 is a pictorial representation of the

status system of the Agilent N6700 Modular Power System:

Figure 1 N6700 Status Model

Looks pretty daunting, doesn’t it? After reading this blog post, it won’t be so

scary anymore. There are many great uses for these registers

in your programs.

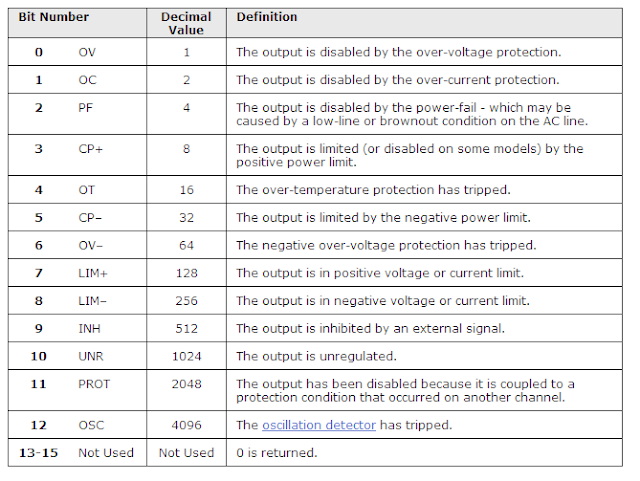

The Questionable Status Group lets you know if your power

supply is in an abnormal operating state.

Sometimes your power supply will be in protect mode when these states

are encountered. You typically want to

query this to make sure that your power supply does not transition to one of

these abnormal states. Here is a list of

all the members of the Questionable Status Group:

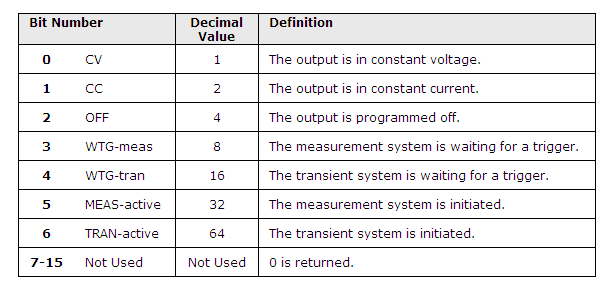

The Operation Status Group provides the normal operating

modes of the power supply. You typically

want to query this register to either make sure that the power supply is either

in the correct operating state or that it has completed some task (such as

initiating a trigger or performing a measurement). Here are the different members of the

Operation Status Group:

Figure 3 Operation Status Group

There are multiple ways to program using the registers. The main way that I query the resisters is

using the Condition Register. The Condition

Register will give you the real time status of the register. Reading this register does not clear it. A good example of using this is when you are

initiating a triggered measurement:

INIT:ACQ (@1) //This initiates

the Acquire trigger system

Do

STAT:OPER:COND? (@1) //Check the status register

status = read

Loop Until (status And 8) = 8

*TRG

Looking at Fig 3, 8 is the WTG_MEAS bit. Once this is true, the unit is ready to be

triggered. This lets you make sure that

you are not triggering the unit before the initiation is done. Note that all of the statuses are referred to

by the instrument by their by the bit weight (listed in the tables as the

decimal value). When you are looking for

multiple statues, you need to add the bit weights.

The other main method of Querying the registers is using the

Event register. The Event Register is

different than the Condition Register in that it keeps track of transitions in

the statuses. It does not matter when the

status change happened, the Event Register will catch it and keep it until it

is read back. You do need to tell the power supply which

statuses you are concerned with using the Negative Transition (STAT:OPER:NTR)

and the Positive Transition (STAT:OPER:PTR) commands. The Event Register is a latching register that

will clear after it is read. An example of

using this register is when you want to make sure that there were no momentary

transitions into an unwanted status. In

the following example, you want to make sure that your power supply does not go

into the Unregulated mode (UNR) before you make a current measurement:

STAT:QUES:PTR 1024,(@1)

// This is the UNR bit

STAT:QUES:NTR 0, (@1) // We are only interested in a positive

transition

Body of your program

STAT:QUES:EVEN? //Query the register

Status = readback

If status And 1024 =1024 then

exit //If the unit went UNR, exit

Else

MEAS:CURR?

(@1) //measure current

Curr=readback

End if

In this case, UNR is bit weight 1024. When the unit transitions to the unregulated

state (the bit transitions from 0 to 1), this bit gets set.

As you can tell by Figure 1, there is a bunch more that you

can do using status, including Service Requests but I will save those for a

possible future blog post.

Please feel free to post any questions or comments here.