A friend of mine approached me a while ago asking for

some help. The fluorescent lamp assembly for his VW Westfalia camper was dead

and, knowing I knew more about electronic devices than he did, figured it was

worth challenging me with it. I was

actually happy to do so. Being involved with DC power conversion of a variety

of forms I was always a bit curious to learn about how fluorescent lamp

assemblies that were powered from low voltage DC worked anyway.

“My lamp does not work; can you look at it for me?”

“I suppose. Did it just stop working? Did you try

anything to get it working again?”

“Well, it really never worked for me. I messed around

with it a little but it did not help. I may have hooked it up backwards.”

“Why do you think you hooked it up backwards?”

“Well, it did not work so I tried reversing the power

connections. That didn’t make it work however.”

“You really should not do that with electronic things!”

I took the lamp home and later when I had chance to look

at it carefully I visually identified several problems. Like many other things

I have repaired, a lot of the times it is not the device itself but rather a

previous owner unintentionally inflicts unnecessary damage on it when

attempting to make repairs. In my

friend’s partial defense, someone previously had already made unsuccessful

attempts at trying to make it work again, unwittingly making things worse.

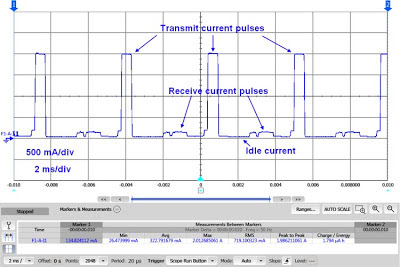

Referring to Figure 1 I unanchored the inverter circuit

board from the back of the lamp assembly for closer inspection. It was

immediately obvious there were problems that would keep it from working:

- The connectors for the wiring to the fluorescent tube

were not making contact.

- A portion of a circuit board trace where the power feeds

in was blown away.

Figure 1: Fluorescent lamp inverter board had obvious

problems

Clearly someone had let the smoke out of it that made it

work! After making repairs to these

problems I then tried powering it up using a power supply with a current limit

to keep things safe. As I expected I was not going to get off that easy. The

power supply went right up to its current limit setting. The lamp still did not

work.

The next step was to probe around the circuit board with

a DMM. With the abuse this lamp assembly

has been subjected to I suspected the switching transistor would be damaged and

sure enough it was measuring shorted. However, after removing it, it seemed to

check out good. Probing around on the board again, a diode adjacent to the

transistor measured shorted as well. Upon its removal it fell in half as a

result of being overheated. I found where the rest of the smoke that makes it

work had come out! I replaced the diode,

reinstalled the transistor and remounted the circuit board. Upon applying power

again the result was a bit different as shown in Figure 2. I managed to

reinstall all the smoke back into it again!

Figure 2: Fluorescent lamp assembly back in working order

While I had a general idea of how it works, now that I had

the fluorescent lamp assembly working again I had take the opportunity to make

some measurements and study the finer aspects of how it works, which I will cover,

coming up in part 2. Stay tuned!