In a previous 2-part posting I talked about what power

and energy is

(part 1 – energy) (part 2 – power). It is pretty straight-forward thing to do to

use a DC power supply for regulating voltage or current. Constant voltage (CV)

and constant current (CC) regulation are standard features of most all DC power

supplies used in testing. However, what if you have an unusual application

calling for applying a fixed amount of energy to your device under test (DUT)?

For example, adding a fixed amount of energy to a calorimeter or chemical

process, or testing the must (or must not) tripping energy of a fuse, or

circuit breaker, or squib or detonator perhaps?

When the resistance of a device remains constant, it is

relatively straight-forward to apply a fixed amount of energy to a DUT. By

applying a fixed voltage or current, the power in the DUT remains constant. Then

the energy is simply:

E = (V2/R)*t = (I2*R)*t

Where E is the energy in watt-seconds or joules, V is

voltage in volts, R is resistance in ohms, I is the current in amps, and t is

time in seconds. All you now need to do is apply the constant voltage or

current for a pre-determined amount of time and you will then be delivering a

fixed amount of energy to your DUT.

Many times however, a lot of DUTs do not maintain

constant loading. The may have a dynamically varying loading by nature or its

resistance dramatically increases as it heats up. How do you regulate a fixed

amount of energy to your DUT under these circumstances? One possibility is to

use one of a few specialized power supplies on the market can regulate their

outputs with constant power. As the DUT’s loading decreases or increases the

power supply will adjust its output accordingly in order to maintain a constant

output power delivered to the DUT. Again

then, by applying this constant power for a pre-determined amount of time you

will then be delivering a fixed amount of energy to your DUT.

Still, for DUTs that do not maintain constant loading, it

is very often not desirable, or outright unacceptable, to apply constant power

sourcing.. It may be you can only apply a fixed voltage or current to your DUT.

What can you do for these circumstances? Time can no longer remain a fixed

value when trying to regulate a fixed amount of energy. The solution becomes

quite a bit more complex, as depicted in Figure 1.

Figure 1: Regulating a fixed amount of energy to a DUT

Putting the solution depicted in Figure 1 into practice

can prove challenging. The watt-hour meter needs to provide a trigger out

signal when the desired watt-hour (or watt-second) threshold level is reached.

This becomes even more challenging if this response time required needs to be

just fractions of a second for this set up. More than likely this may become a

piece of customized hardware.

Interestingly this very set up can be programmatically

configured within our N6900A and N7900A series Advanced Power System (APS)

power supplies. These products have Amp-hour and Watt-hour measurement

integrated into their measurement systems. Not only can you measure these

parameters, there is a programmable way to act on them in a variety of ways as

well, which is the expression signal routing. Logical expressions can be

programmed and downloaded into APS, which then acts on them at hardware-level

speeds. Creating and loading the signal

routing expression into the APS unit is simplified by using the N7906A Power

Assistance software, which let me do it graphically, as shown in Figure 2.

Figure 2: Graphically developing and loading an energy

limit setting into an Agilent APS unit

In Figure 2 a threshold comparator was set to generate a

trigger output at a level of 0.0047 watt-hours. This trigger was then routed to

the output transient system, to cause the output to transition to a new output

level when triggered. I had entered in zero volts as the triggered output

level. Thus when the watt-hour reading reached its trigger point, the output

went to zero, cutting off any more power and energy from being delivered to the

DUT.

The SCPI command set for this signal routing expression

is also generated from this software utility by clicking on “SCPI to clipboard”.

This saves on the effort generating the code manually if you are incorporating

the expression into a larger test program. For this expression the code

generated is:

:SENSe:THReshold1:FUNCtion WHOur

:SENSe:THReshold1:WHOur 0.0047

:SENSe:THReshold1:OPERation GT

:SYSTem:SIGNal:DEFine EXPRession1,"Thr1"

:TRIGger:TRANsient:SOURce EXPRession1

To test things out a 1.18 ohm resistive load was used to

draw 84.75 watts for a 10 volt output setting. The output cut back to zero

volts at nearly 200 milliseconds, as expected. This is shown in the

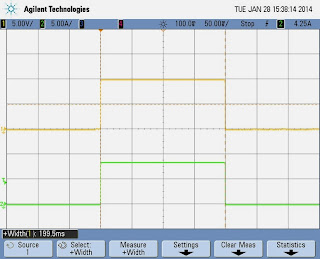

oscilloscope capture in Figure 3.

Figure 3: APS output for an 84.75 watt load and energy

limit set to 0.0047 watt-hours

The load power was then doubled by increasing the output

voltage to 14.142 volts. The APS output cut back to zero volts in half the

time, delivering the same amount of energy, as expected. This is depicted in

the oscilloscope capture in Figure 4.

Figure 4: APS output for a 169.5 watt load and energy

limit set to 0.0047 watt-hours

While using a resistor makes it easy to see that

a set amount of energy is being delivered to the load. However, being able to

act on a real time watt-hour energy measurement makes it very practical to do

deliver a fixed amount of energy, regardless of the dynamic nature of the load

over time.