As I mentioned in a previous post, we have devoted a lot of time writing about protecting your device under test (DUT) from the two main DUT-destroying forces available from a power supply: excessive voltage and excessive current. Click here for one of the latest posts including a list to the other posts.

Today I’d like to cover another topic that can cause DUT failure due to a power supply. Some DUTs have multiple DC inputs and some of these multiple-input DUTs are sensitive to the order in which the inputs turn on or turn off. Subjecting the device to an uncontrolled sequence could cause latch-up or excessive current to flow resulting in compromised reliability or even immediate catastrophic failure of the DUT. So properly sequencing the multiple voltages at turn on and off is essential. My colleague, Ed Brorein, wrote a very similar post last year (click here) but I thought this topic was worth repeating especially since we added another series of power products with higher power that has this capability.

Various methods have been used in an effort to address the potential problem associated with improperly sequenced power inputs. Diodes can be placed from one input to another to clamp the voltage thereby preventing one input voltage from going too far above or below another input voltage but this method has limited effectiveness and variable results. Relays can be put in series with each input and controlled with timing circuitry but the relays introduce variable series impedance and timing is imprecise. FETs with associated control circuitry can be placed in series with each input however this method requires significant design time and adds complexity to the setup. Multiple DC power supplies can be controlled through software, but once again, timing is imprecise and response times can be slow.

Several years ago, I wrote an application note on a closely related topic (click here). The method that is most precise and introduces the fewest complications is to use a power supply system that has output sequencing integrated into the system itself. Keysight has several power supply systems that can accommodate precise output sequencing: the N6700 Modular Power System, N6705 DC Power Analyzer, and the more recently released N6900/N7900 Advance Power System. Each system offers the ability to precisely control the turn-on and turn-off sequence of multiple outputs. Timing is set with sub-millisecond resolution. Synchronization across systems is also possible to facilitate timed shut downs of larger numbers of power supply outputs for your DUT inputs. The above mentioned application note specifically addressed the topic of how to configure the system to properly shut down your DC inputs in sequence upon a fault generated by any of the system power supplies.

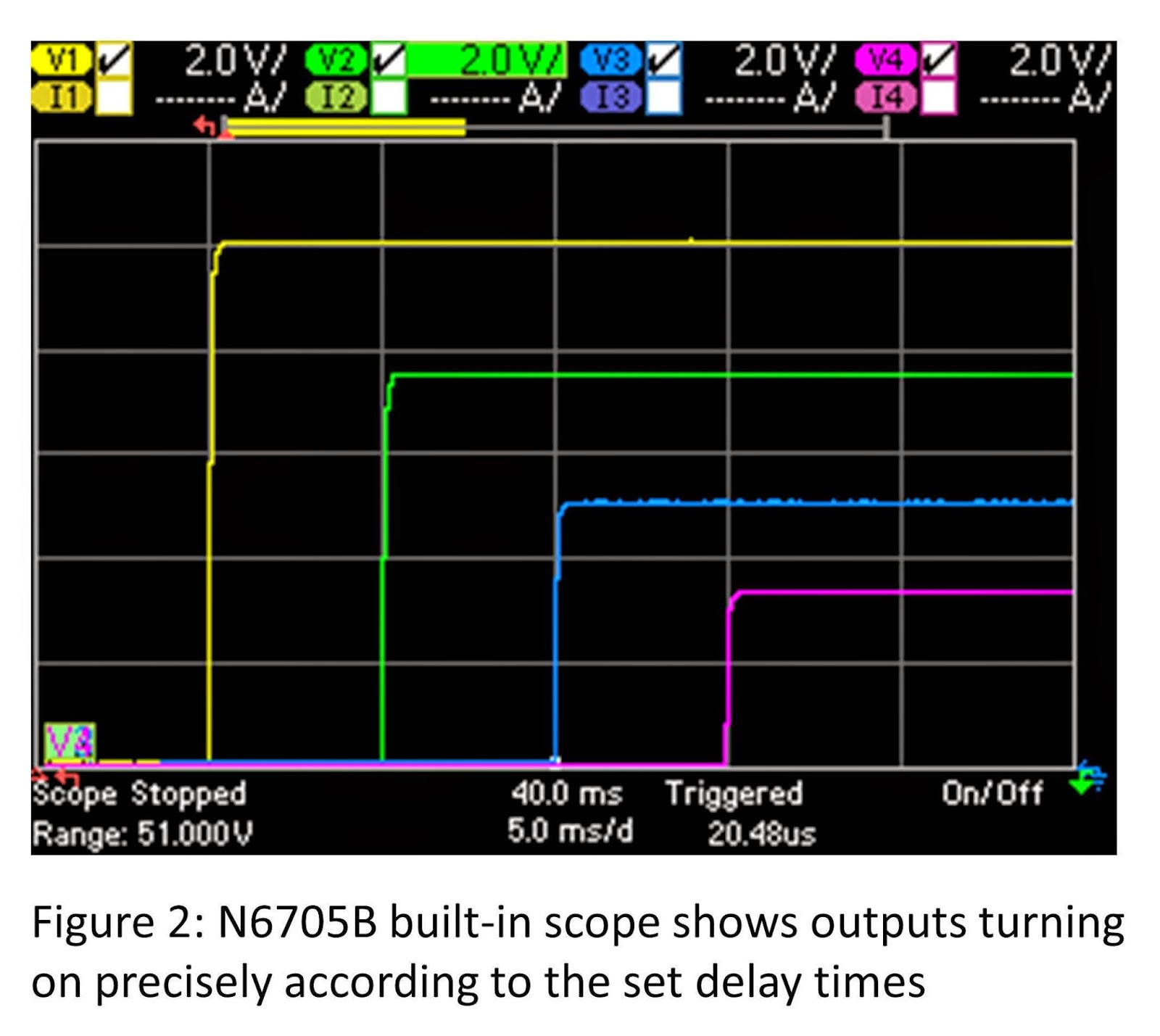

Below is a simple example of a sequenced turn on of four outputs in an N6705B mainframe. The sequencing is facilitated by setting a different turn-on delay time for each of the outputs (turn-off delays can be set independently). When all outputs are told to turn on simultaneously, the delays are activated resulting in a precisely controlled sequenced turn on. Figure 1 shows how easy it is to implement the delays for a turn-on event. In this case, I used four power supply outputs in an N6705B mainframe with delays set to 5 ms, 10 ms, 15 ms, and 20 ms. I set the output voltages to 10 V, 7.5 V, 5 V, and 3.3 V. You can also set the output voltage rise time (slew rate) independently for each output. Figure 2 shows the results using the scope that is built into the N6705B mainframe.

So you can see that with the proper power supply system, sequencing your multiple DC power supply inputs on your device to protect it from damage is easy. Keysight provides you with the solution to do just that adding to our arsenal of features that protect your valuable DUT.

Showing posts with label output sequencing. Show all posts

Showing posts with label output sequencing. Show all posts

Monday, September 29, 2014

Friday, February 15, 2013

Addressing the challenge of sequencing multiple bias supplies on and off

A challenge test engineers are perennially faced with is

how to best sequence the bias voltages powering their DUT, when their DUT

requires several bias voltages. Many DUTs are sensitive to sequencing and an

improper sequence may lead to the DUT hanging up, or worse, suffer damage as a

consequence. Not only is sequencing an issue when powering the DUT on, but it can

also be an issue when powering the DUT down as well. In addition to sequencing,

the slew rates of the various bias voltages can likewise be important to the

DUT correctly powering on.

Simply relying on the timing of output-on and output-off

commands sent from the test system controller to all the system DC power

supplies individually tends to be far too imprecise, especially for critical

sequencing timing requirements. The actual turn-on time of a typical system DC

power supply can be many tens of milliseconds, and will vary considerably

between different models of power supplies. The turn-on and turn-off times of

each will need to be carefully characterized in order to know when a command

for a specific bias voltage needs to be sent in relation to the other bias

voltages. It is very likely the sequence of commands sent for outputs to turn

on or off may be in a different sequence to the outputs actually changing, due

to delay differences between different DC power supplies! An even bigger

problem however is most system controllers are PCs which may randomly

experience a large delay in sending out a command, if a higher level service

request interrupts and pre-empts execution of the test program.

An alternative approach often taken is adding some custom

hardware to control output sequencing. This can assure correct sequencing, but

adds a lot of complexity, is usually inflexible, and may introduce other issues

and compromises.

At Agilent we added system features to our N6700 series

multiple output modular DC power system that support correct power-on and

power-off sequencing. The output-on and output-off controls for the individual outputs

get grouped together. The N6700 platform knows and compensates for the actual

delays of all the various DC power output modules so that the desired delay

value entered will be what is accurately achieved. Figure 1 shows setting up an

N6705A to achieve a desired turn-on sequence of DC outputs for powering up a PC

mother board. Figure 2 shows the actual result. A more detailed description of

this PC motherboard example is given in our application note: “Biasing Multiple

Input Voltage Devices in R&D”. While the N6705B DC Power Analyzer mainframe

is regarded as being primarily for R&D, which this app note is referencing,

the low profile rack-mountable N6700 series mainframes have these very same

features and suit automated test systems in manufacturing and other

environments.

Figure 1: Setting Output Delays

Figure 2: Output Turn-on Sequence Results

Just like setting up the power-on sequence, separate

delays for power-off can also be entered, as seen in the set up screen shown in

Figure 1, for the expected shut down of the DUT. However, what if there is an

emergency shut down due to an abnormal condition and you still want to assure a

certain power-off sequence? A colleague worked out the procedure for setting up

the N6700 series DC power system to provide an orderly shutdown of the outputs,

in the event of a problem on one of the outputs. In this example it happens to

be an overvoltage condition on one of the outputs, but any of a number of fault

conditions can be acted on to initiate an orderly shutdown. Details of this

procedure are provided in another application note; “Avoid DUT Damage by

Sequencing Multiple Power Inputs Off Upon a Fault Event”.

So when faced with the challenge of having to properly

sequence multiple DC bias voltages powering your DUT, reconsider trying to

engineer a solution to accomplish this. Instead, look for features that provide

this kind of capability in the system DC power supplies you are looking to use,

already built-in. It makes a lot of sense having sequencing built into the

power supplies and it will make your life a lot easier!

Subscribe to:

Posts (Atom)