Often there is the need for generating high-power current

pulses, typically of short duration, and having rise and fall times on the

order of microseconds. This is a common need when testing many types of power

semiconductors, for example.

When looking for a DC power supply capable of generating

very fast, high-power current pulses, one will find there are not a lot of

options readily available that are capable of addressing their needs. There are

specialized products dedicated for specific applications like this; an example

of this is Keysight’s B1505A purpose-built semiconductor test equipment. They

are capable of generating extremely fast, high-power current pulses.

Apart from specialized products however, DC power

supplies generally to not offer this kind of speed when operating in a constant

current mode (or current priority mode). One exception that comes to mind that

we provide is our N6782A and N6782A DC source measure modules. They can create

fast current pulses having just a couple of microseconds of rise and fall time.

However, they are limited to 20V, 3A, and 20W of output. Most of the higher

power, more general-purpose DC sources are not able to generate these kinds of

fast, high-power current pulses and most are really more optimized to operate

as voltage sources.

One alternative to consider for generating fast,

high-power current pulses when working with general-purpose test equipment is

to use an electronic load. You may initially say to yourself “an electronic

load is for drawing pulses of current, not sourcing them!” but when coupled to

a standard DC power supply operating as a voltage source, the setup is able to source

fast, high-power current pulses. Most electronic loads are designed to have

very fast current response. To illustrate this, I helped one customer needing

to test their high brightness LED (HBLED) arrays with fast pulses of current.

This was accomplished with the setup shown in Figure 1.

Figure 1: Load setup generating fast, high power current

pulses for LED array testing

In this setup the power supply operates as a fixed,

static voltage source. The power supply’s output voltage is set to the combined

total of the full voltage needed to drive the HBLED array at full current plus

the minimum voltage needed for the electronic load. The minimum voltage

required for the electronic load is when it conducting maximum current and most

of the power supply voltage is then applied across the HBLED array. The

electronic load’s required minimum voltage is that which supports its operation

in its linear range and maintains full dynamic response characteristics. In the

case of Keysight electronic loads this minimum voltage for linear dynamic

operation is 3 volts. Conversely the

maximum voltage required for the electronic load is when it drops down to

minimum current level, where the power supply’s voltage is instead now being

dropped across the electronic load instead of the HBLED array. Note that the

electronic load may need to maintain a very small amount of bleed current to

maintain linear operation in order to provide truly fast rise and fall times.

In this way the electronic load is able to regulate the current across the full

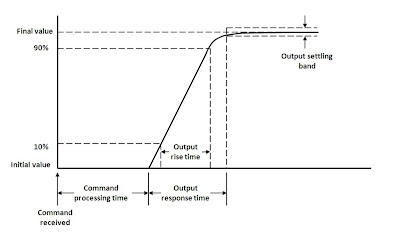

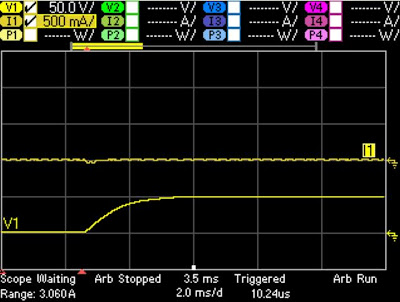

range with excellent dynamic response. This can be seen in Figure 2 where we were

able to achieve approximately 15 microsecond rise time right from the start.

Figure 2: Pulsed current rise time in HBLED array

One advantage of this setup is the wide range of voltage

and power that can be furnished to the DUT using a relatively low power electronic

load. A common characteristic of electronic loads is that they can dissipate a

given amount of power over an extended range of current and voltage. When the

electronic load is at maximum current it is at minimum voltage. Conversely when

it is near or at zero current it is then at its maximum voltage. In both cases

there is only a small amount of power that the electronic load needs to

dissipate. For an HBLED array it does not conduct a lot of current until it

reaches about 75% of its full operating voltage. As a result the electronic

load does not see a lot of power even on a transient basis. For this particular

situation we chose to use the Keysight N3303A 240V, 10A, 250W electronic load.

This gave a wide range of voltage, current, and power for testing a comparably wide

range of different HBLED array assemblies.

So next time you need to source fast, high-power current

pulses, you may want to think “load” instead of “source”!