Most electronic loads provide constant current (CC),

constant resistance (CR) and constant voltage (CV) loading. Some also offer

constant power (CP) loading as well. The primary reason for this is this gives

the test engineer a choice of loading that best addresses the loading

requirement for the DUT, which invariably is some kind of power source.

Most usually the device should be tested with a load that

reflects what the loading is like for its end use. In the most common case of a

device being predominantly a voltage source the most common loading choices are

either CC or CR loading, which we will look at in more detail here. Some feel

they can be used interchangeably when testing a voltage source. To some extent

this is true but in some cases only one or the other should be used as they can impact

the DUT’s performance quite differently.

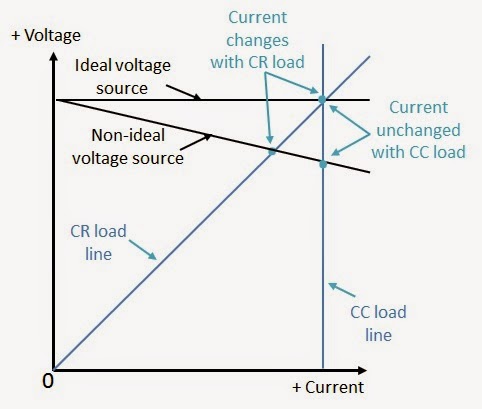

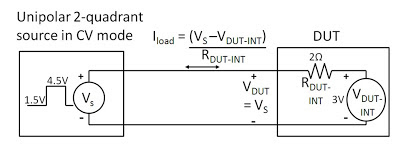

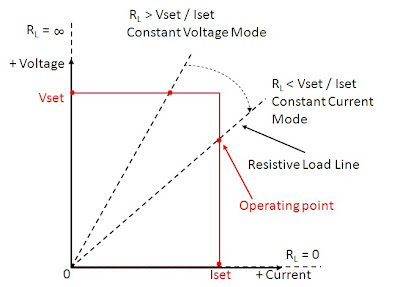

Let’s first consider static performance. In Figure 1 we

have the output characteristics of an ideal voltage source with zero output

resistance (a regulated power supply, for example) and a non-ideal voltage

source having series output resistance (a battery, for example). Both have the same open circuit (no load) voltage.

Superimposed on these two source output characteristics are two load lines; one

for CC and one for CR. As can be seen they are set to draw the same amount of

current for the ideal voltage source. However, for the non-ideal voltage

source, while the CC load still continues to draw the same amount of current in spite of the voltage drop,

not surprisingly the CR load draws less current due to its voltage-dependent

nature.

Figure 1: CC and CR loading of ideal and non-ideal

voltage sources

CC loading is frequently used for static power supply

tests for a key reason. Power supplies are usually specified to have certain

output voltage accuracy for a fixed level of current. Using CC loading assures the

loading condition is met, regardless of power supply’s output voltage being low

or high, or in or out of spec. Non-ideal voltage sources, like batteries,

present a little more of a problem and are often specified for both CC and CR

loading as a result, to reflect the nature of the loading they may be subjected

to in their end use. Due to a battery's load-dependent output voltage, trying to use one type of loading in place the other becomes

an iterative process of checking and adjusting loading until the acceptable operating

point is established.

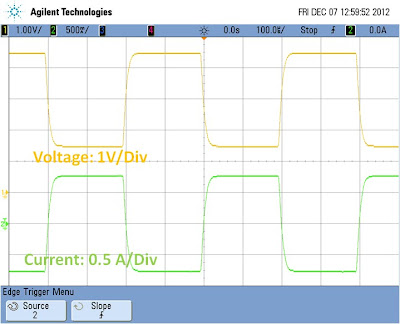

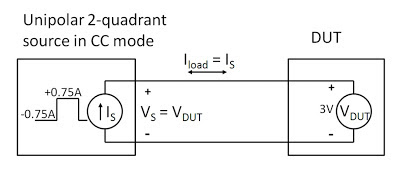

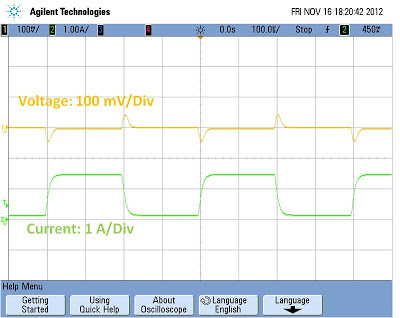

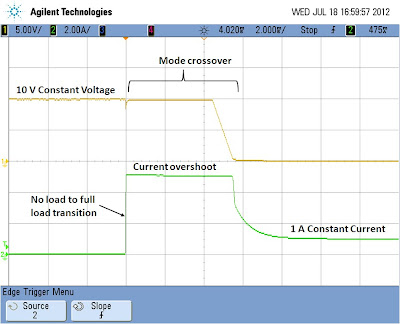

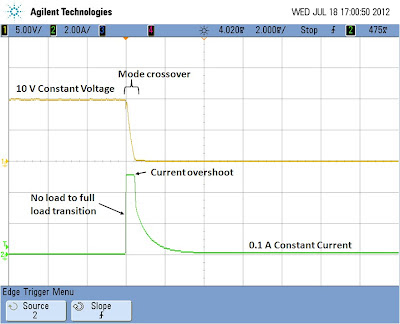

Let’s now consider dynamic performance. CC loading generally has a greater impact on a

power supply’s ability to turn on as well as its transient performance and

stability, in comparison to CR loading. When the power supply first starts up

its output voltage is at zero. A CR load would demand zero current at start up.

In comparison a CC load still demands full current. Some power supplies will

not start up properly under CC loading. With regard to transient response and

stability, CR loading provides a damping action, increasing current demand when

the transient voltage increases and decreases demand when the transient voltage

decreases, because the current demand is voltage dependent. CC loading does not

do this, which can negatively influence transient response and stability

somewhat. Whether CC or CR loading is used depends on what the power supply’s

specifications call out for the test conditions. Batteries have some dynamic

considerations as well. Their output response can be modeled as a series of

time constants spanning a wide range of time. This presents somewhat of a

moving target for an algorithm that uses an iterative approach to settling on

an acceptable operating point.

This is just a couple of examples of how a load’s

characteristic affects the performance of the device it is loading, and why electronic

loads have multiple operating modes to select from, and worth giving thought next

time towards how your device is affected by its loading!