Our N6900 and N7900 series Advanced Power System (APS) DC

power supplies are some of our most sophisticated products, setting new levels

of performance and capabilities on many fronts. They come in 1kW and 2kW power

levels as shown in Figure 1 and can be grouped together to provide much greater

power levels as needed.

Figure 1: N6900 and N7900 Advanced Power System 1kW and

2kW models

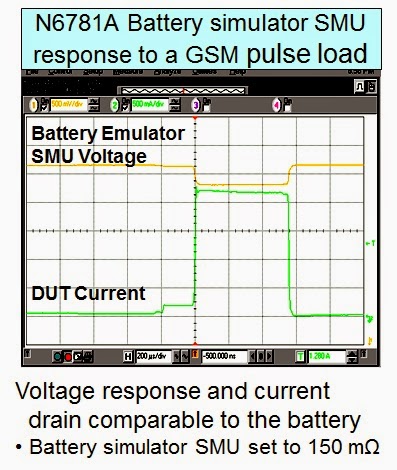

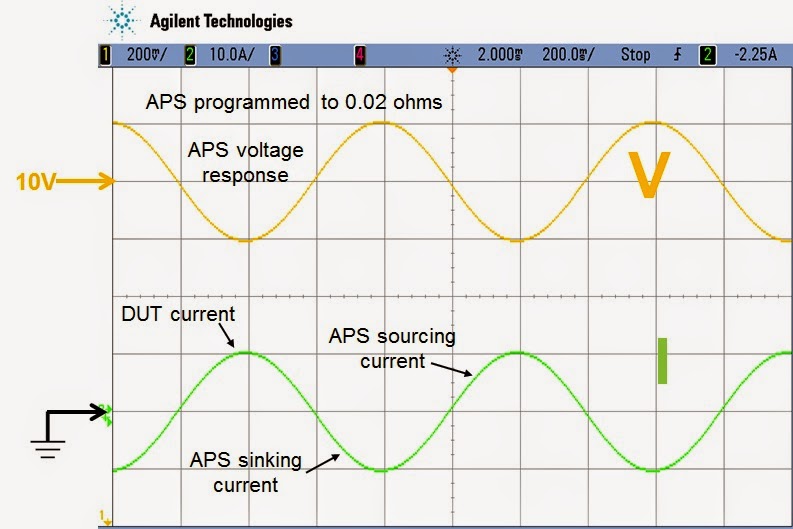

Most noteworthy is that these can be turned into full

two-quadrant DC sources by connecting up the optional 1kW N7909A Power Dissipator

(2 needed for 2kW units) providing 100% power sinking capability. This makes

APS an excellent solution for battery, battery management and many alternative

energy applications, where both sourcing and sinking power are needed.

- The N6900 series DC power supplies are designed for ATE applications where high test throughput and high performance is critical.

- The N7900 series dynamic DC power supplies are designed for ATE applications where high speed dynamic sourcing and measurement is needed, in additions to high performance.

A lot more about these products is covered in another

post on our General Purpose Electronic Test Equipment (GEPTE) blog when they

were first announced. This is a great resource for learning more about APS and

can be accessed from the following link: “New Advanced Power System: Designed to Overcome Your Toughest Test Challenges”

If you are a regular visitor to the “Watt’s Up?” blog no

doubt you have seen we have shared a lot about how to do things with the N6900

series and N7900 series APS to address a number of difficult test challenges. A

lot of times it would have otherwise required additional equipment or custom

hardware to accomplish these tasks. While many of these examples are suitable

for the N6900 and N7900, a good number of times examples make use of the

additional capabilities only available in the N7900 series.

In certain test situations the N6900 series APS would be

a great solution and lower cost than the N7900 series, if only it also had a

certain additional capability. To this end Keysight has recently announced four

new performance options for the N6900 series APS to address a specific test

need you may have, as follows:

- Accuracy Package (option 301): Adds a second seamless measurement range for current

- Measurement Enhancements (Option 302): Adds external data logging and voltage and current digitizers with programmable sample rates

- Source and Speed Enhancements (Option 303): Adds constant dwell arbitrary waveforms and output list capability, and faster up and down programming speed

- Disconnect and Polarity-Reversal Relays (Option 760 and 761): Provides galvanic isolation and allows output voltage to be switched between positive and negative values